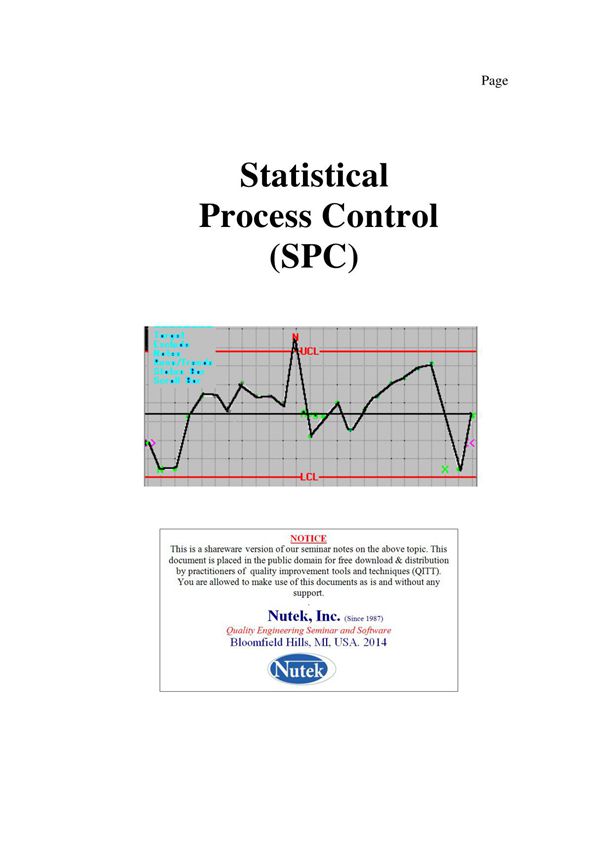

StatisticalProcessControl(SPC)isamethodofqualitycontrolthatusesstatisticalmethodstomonitorandcontrolaprocess.Ithelpsensurethattheprocessoperatesefficiently,producingmorespecification-conformingproductswithlesswaste.SPCcanbeappliedtoanyprocesswheretheoutputcanbemeasured,suchasmanufacturing,serviceindustries,andhealthcare.OneofthekeyadvantagesofSPCisitsabilitytodetectvariationsintheprocessbeforetheyresultindefects.Bycollectingandanalyzingdatainreal-time,SPCenablesoperatorstodistinguishbetweencommoncausevariations(inherenttotheprocess)andspecialcausevariations(duetoexternalfactors).Thisdistinctioniscrucialfortakingappropriatecorrectiveactions,suchasadjustingtheprocessparametersorinvestigatingtherootcauseoftheissue.Toolslikecontrolcharts,histograms,andParetoanalysisarecommonlyusedinSPCtovisualizedatatrendsandidentifyareasforimprovement.SPCisnotjustaboutmaintainingqualitybutalsoaboutcontinuousimprovement.Byconsistentlymonitoringprocessperformanceandmakingdata-drivendecisions,organizationscanreducevariability,enhanceproductquality,andincreasecustomersatisfaction.ImplementingSPCrequirespropertrainingandcommitmentfromalllevelsoftheorganization,asitinvolvesaculturalshifttowardsproactiveproblem-solvingandqualityawareness.